Description

SPM Calibration Specimens

Overall Benefits:

– Easier testing of your SPM. – Improved accuracy of critical dimension measurements. – Accuracy: 0.5% (1 std. dev.).

Features and Benefits:

– Holographic fabrication – assures high accuracy and precision. – Pattern height > 100nm – provide excellent image contrast. – Uniform coverage of entire chip – save time (can image anywhere).

Description:

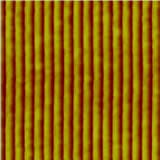

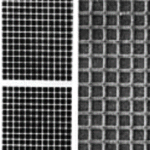

– Nominal calibrated dimensions: 300 or 700 nm. – Calibration certificate: supplied with each sample, stating the dimension to the nearest 1 nm. – Pattern types: 1- or 2—Dimensional. The calibrated dimension is the same for both axes for the 2-D standard. – Feature geometry: – parallel ridges (1-D, 300 or 700nm) – cylindrical posts (2-D 300nm)

– diamond-shaped posts (2-D 700nm) – Physical Size: 3 mm x 4 mm x 0.5mm. – Substrate: Silicon wafer. – Top surface: Tungsten film. The 1-D standards can be scanned using any AFM mode, including contact mode. The 2-D standards can be scanned using modes such as Tapping Mode™, intermittent contact, and non-contact.

Model 150-1D

Accurate measurements of sub 0.5 micron features are increasingly important as nanotechnology develops an

Model 750-HD

High Durability Calibration Reference Specimen for AFM and STM Each specimen is supplied with a calibration certificate. Can be used for AFM, STM and SEM. Has been used successfully in a hot water AFM.

| Nominal pattern dimensions | Pitch 750 nm |

| Height 100 nm | |

| Nominal specimen dimensions | 6.35 nm diameter, 0.3 mm thick |

| Composition | Solid Nickel |

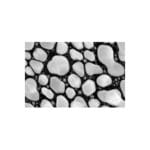

Model PT

Phase Imaging Test Specimen (verify TappingMode™ phase contrast and resolution). Phase Imaging is a sharp probe, which is brought into proximity with the specimen surface. The probe is oscillated vertically near its mechanical resonance fre-quency. As the probe lightly taps the surface, the amplitude of oscillation is reduced and the AFM uses this change in amplitude in order to track the surface topography. In addition

Models 300-2D, 300-1D, 700-2D and 700-1D

All mounted on 15 mm steel disk.

Models 300-1D and 300-2D

Models 300-2D

Models 700-1D

Models 700-2D

Avis

Il n’y a pas encore d’avis.